Robot Coping Machine Vision Uses

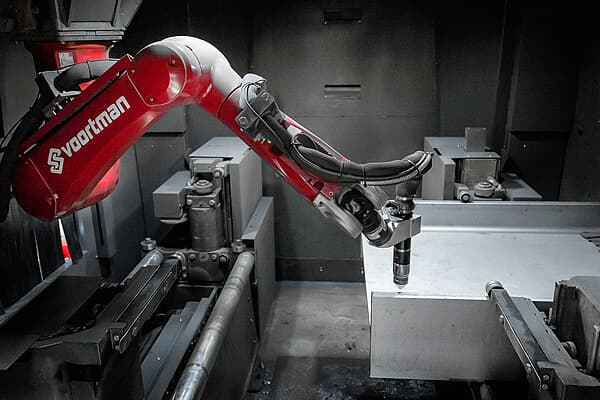

Coping is the most versatile process. A robotic plasma processor is capable of providing an all-in-one solution. With a plasma unit or robot, you can process any number of things: rat holes, seismic design connections such as jay-allan, "dog bone" cuts and copes at the product's trail end.

METEOR-1200 has the ability to cut down on your labor, whether you are drilling or performing on-site assembly. METEOR-1200 has the ability to drill beams and angles, flat sheets, and other suitable geometry. With the state of art control system, you can also mill slots and pockets.